Growth Antimicrobial Coatings: Reducing Microbial Growth

Introduction

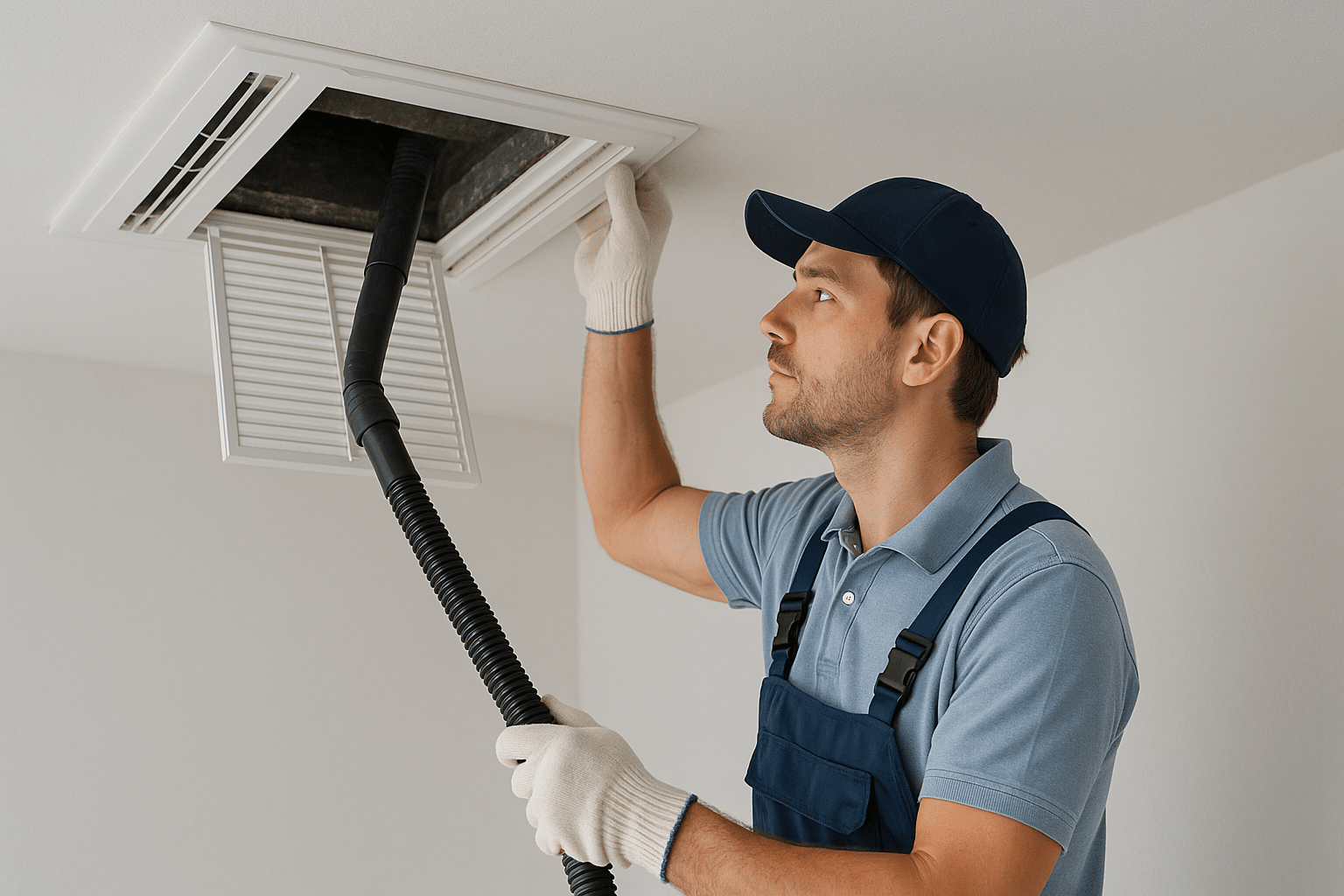

Understanding Reducing Microbial Growth: Antimicrobial Coatings Vs. is essential. Reducing microbial growth inside HVAC systems is essential for maintaining clean indoor air quality (IAQ) and preventing health issues. Antimicrobial coatings and biocide treatments are two popular methods, each with its own set of advantages and disadvantages. This article provides a comprehensive comparison to help you decide which approach might be best suited for your needs.

Understanding Reducing Microbial Growth: Antimicrobial Coatings vs. Biocides

Contents

- 1 Understanding Reducing Microbial Growth: Antimicrobial Coatings vs. Biocides

- 2 Reducing Microbial Growth: Antimicrobial Coatings Vs. – Benefits of Antimicrobial Coatings

- 3 Reducing Microbial Growth: Antimicrobial Coatings Vs. – Limitations of Antimicrobial Coatings

- 4 Biocide Treatments: Advantages and Disadvantages

- 5 Comparison Table: Antimicrobial Coatings vs. Biocides

- 6 Expert Tips for Reducing Microbial Growth in HVAC Systems

- 7 Frequently Asked Questions (FAQ)

- 8 Conclusion: Choosing the Right Solution

Microorganisms such as bacteria and fungi can thrive in HVAC systems, particularly when conditions are humid or dusty. These microorganisms can release spores that circulate through the air conditioning system, leading to potential health issues for building occupants. This relates directly to Reducing Microbial Growth: Antimicrobial Coatings Vs..

What Are Antimicrobial Coatings?

Antimicrobial coatings contain substances that inhibit or prevent microbial growth on surfaces. These coatings can be applied to various parts of the HVAC system, including ducts and coil surfaces, to reduce microbial colonization. When considering Reducing Microbial Growth: Antimicrobial Coatings Vs., this becomes clear.

Biocide Treatments

Biocides are chemical substances used in water systems to kill or inhibit the growth of microorganisms. In HVAC applications, biocides can be added to coolant fluids or distributed through the air stream to target and eliminate microorganisms. The importance of Reducing Microbial Growth: Antimicrobial Coatings Vs. is evident here.

Reducing Microbial Growth: Antimicrobial Coatings Vs. – Benefits of Antimicrobial Coatings

Antimicrobial coatings offer several advantages:

- Persistent Effectiveness: The antimicrobial properties are continuously active, even after cleaning and maintenance.

- Ease of Application: Can be applied to existing systems without major disruptions.

- Long-Term Protection: Provides long-lasting protection against microbial growth.

Reducing Microbial Growth: Antimicrobial Coatings Vs. – Limitations of Antimicrobial Coatings

Despite their benefits, antimicrobial coatings have some limitations:

- Cost Consideration: The initial application and ongoing costs can be higher compared to biocide treatments.

- Surface Preparation: Proper surface preparation is crucial for the coating’s effectiveness.

Biocide Treatments: Advantages and Disadvantages

Biocides offer a different approach to reducing microbial growth, each with its own set of pros and cons:

- Cost-Effective: Typically less expensive than antimicrobial coatings.

- Quick Acting: Effective immediately upon application or addition to the system.

Disadvantages of Biocide Treatments

- Toxicity Concerns: Some biocides can be harmful if not used properly, potentially leading to indoor air quality issues.

- Dependence on Application: The effectiveness is highly dependent on regular and proper application methods.

Comparison Table: Antimicrobial Coatings vs. Biocides

| Antimicrobial Coatings | Biocide Treatments | |

|---|---|---|

| Type of Application | Covering surfaces, e.g., ducts and coils | Added to coolant fluids or air streams |

| Efficacy Duration | Persistent (long-term) | Short-lived (requires regular application) |

| Initial Cost | Higher than biocides | Lower, but recurring costs for application and monitoring |

| Ease of Use | Simpler, as it requires fewer application steps | Dependent on proper application methods |

| Risk of Indoor Contamination | Potentially lower risk due to persistent coating | Higher risk if not applied correctly or monitored properly |

Expert Tips for Reducing Microbial Growth in HVAC Systems

- Regular Maintenance: Perform routine inspections and cleaning to prevent microbial buildup.

- Proper Ventilation: Ensure adequate ventilation to reduce humidity levels inside the system.

- Use of HEPA Filters: Install high-efficiency particulate air (HEPA) filters to trap airborne contaminants.

- Optimal Temperature and Humidity Control: Maintain optimal temperature and humidity levels to inhibit microbial growth.

Frequently Asked Questions (FAQ)

- Q: Which is more effective?

- A: Both methods can be effective, but the choice depends on specific conditions and needs. Antimicrobial coatings offer long-term protection, while biocides are quick-acting.

- Q: Are there any risks associated with these treatments?

- A: Antimicrobial coatings generally pose lower risk, but proper application and selection of biocides is crucial to avoid indoor air quality issues.

- Q: Can I use both methods together?

- A: Yes, combining both approaches can provide a more comprehensive solution. However, ensure compatibility between the products used.

Conclusion: Choosing the Right Solution

Choosing the right method to reduce microbial growth in HVAC systems depends on your specific needs and conditions. Antimicrobial coatings offer long-term protection with minimal risk, while biocide treatments can be more cost-effective but require careful application. Understanding Reducing Microbial Growth: Antimicrobial Coatings Vs. helps with this aspect.

Consulting with a professional HVAC specialist can help you determine which solution is best for your system. Regular maintenance and proper cleaning practices are also crucial to maintaining clean indoor air quality. Understanding Reducing Microbial Growth: Antimicrobial Coatings Vs. is key to success in this area.

Leave a Reply